If you’re searching for the 15 best high-end ceramic kilns for professional pottery, I can help. I’ve compiled top models with advanced temperature control, durable construction, and versatile features like programmable profiles and large capacities. These kilns suit serious artists and collectors who want reliable, high-performance firing. Keep exploring to discover the ideal kiln that matches your creative needs and learn more about the must-have accessories for flawless results.

Key Takeaways

- High-end ceramic kilns offer precise temperature control, uniform heat distribution, and reliable performance for professional artists.

- Features like reusable kiln supports, refractory surfaces, and advanced insulation enhance durability and firing quality.

- Many models support multiple firing cycles, reducing long-term costs and ensuring consistent results.

- Professional kilns often include customizable supports and accessories for complex or large-scale ceramic projects.

- Top picks emphasize safety, energy efficiency, and compatibility with various ceramic and glass materials.

Ceramic Porous Refractory Mat with Support Nails for Kiln Firing

If you’re a ceramic hobbyist or professional looking for reliable support during kiln firing, the Ceramic Porous Refractory Mat with Support Nails is an excellent choice. This high-quality, reusable mat is made from premium refractory ceramic fiber, resistant to temperatures up to 2462℉ (1350℃). Its porous design with evenly spaced holes allows for easy insertion and adjustment of 60 moveable support nails, accommodating various ceramic pieces. The mat stabilizes your work, prevents sliding, and ensures even firing. Plus, with a durable build that can last around 100 firing cycles, it offers long-term value and consistent performance for all your firing needs.

Best For: ceramic hobbyists, professional potters, and clay artists seeking a durable and adjustable support solution for kiln firing.

Pros:

- Reusable up to 100 times, offering excellent long-term value.

- High-temperature resistant up to 2462℉ (1350℃), suitable for various firing needs.

- Porous design with movable support nails provides flexible and stable placement for different ceramic pieces.

Cons:

- Slightly heavy at 8.1 ounces, which may be cumbersome for some users to handle frequently.

- Requires careful adjustment of support nails to prevent shifting during firing.

- Limited size (3.94×3.94 inches), which may not accommodate very large ceramic pieces without additional support.

50 Pack Pottery Kiln Nails – High-Temperature Ceramic Refractory Cone Support Nails

For ceramic artists and professionals who demand reliable support during high-temperature firings, Pack Pottery Kiln Nails are an excellent choice. These high-temperature ceramic refractory cone support nails withstand temperatures up to 2516℉, ensuring consistent performance during intense firings. They help prevent glaze from sticking to kiln shelves and promote even heat distribution, resulting in professional-quality, unmarked pieces. Made from durable alumina, they’re reusable up to 10 times, making them cost-effective. Easy to install and remove, these versatile nails provide stable support for both small and larger pottery pieces, reducing warping or tipping throughout the firing process.

Best For: ceramic artists and professionals seeking reliable, high-temperature support for firing their pottery and ceramic pieces.

Pros:

- Withstands temperatures up to 2516℉ ensuring durability during intense firings

- Reusable up to 10 times, offering cost-effective support for multiple projects

- Easy to install and remove, providing stable support and preventing warping or tipping

Cons:

- May require careful handling to avoid breakage due to ceramic material

- Limited to high-temperature ceramic applications, not suitable for low-temperature projects

- Reuse potential might diminish if nails are damaged or worn out over time

Penguin Pottery Liquid Kiln Wash (16 oz)

High-End Ceramic Kilns are designed for serious ceramic artists who demand reliable and efficient firing solutions. Penguin Pottery’s Liquid Kiln Wash (16 oz) is a must-have for protecting kiln shelves. It’s ready to use—no mixing needed—and creates a durable, protective coating that prevents glaze from sticking during firing. Applying several thin coats with a brush or sprayer ensures even coverage, extending the life of your shelves and making clean-up easier. Just avoid applying it to fiber or silicon carbide shelves. Proper use of this kiln wash helps guarantee smooth firing, reduces damage, and keeps your kiln in top condition for professional results.

Best For: Serious ceramic artists and professionals seeking reliable kiln shelf protection to ensure smooth firing and easy cleanup.

Pros:

- Ready-to-use, no mixing required for quick application

- Provides a durable, protective coating to prevent glaze sticking

- Extends the lifespan of kiln shelves and simplifies cleanup

Cons:

- Not suitable for fiber-based or silicon carbide shelves

- May require multiple coats for optimal coverage

- Needs thorough drying between coats to ensure effectiveness

Ceramic Tripod 3-Point Kiln Support (Pkg/6)

Ceramic Tripod 3-Point Kiln Supports are essential for anyone aiming to achieve a professional finish on glazed ware. These stilts measure about 1-1/8 inches between outside points and stand 5/8 inches high, with sharp metal tips designed to leave minimal marks. Made from durable ceramic, they withstand temperatures up to 2025°F (Cone 03) and easily release after firing, ensuring your delicate pieces stay pristine. Sold in packages of six by National Artcraft, they’re highly rated for their reliability and longevity. I find them indispensable for glaze firing, especially when working with detailed or fragile ceramics that require minimal contact marks.

Best For: artists, ceramicists, and pottery enthusiasts seeking reliable kiln supports for glaze firing of delicate or detailed ceramic pieces.

Pros:

- Minimal marks on glazed ware due to sharp metal points

- High-temperature durability up to 2025°F (Cone 03)

- Easy release after firing, preserving the finish of delicate pieces

Cons:

- Limited to firing temperatures below 2025°F, unsuitable for higher-temperature applications

- Only available in packages of six, which may be more than needed for small projects

- Ceramic construction may require careful handling to avoid breakage during setup

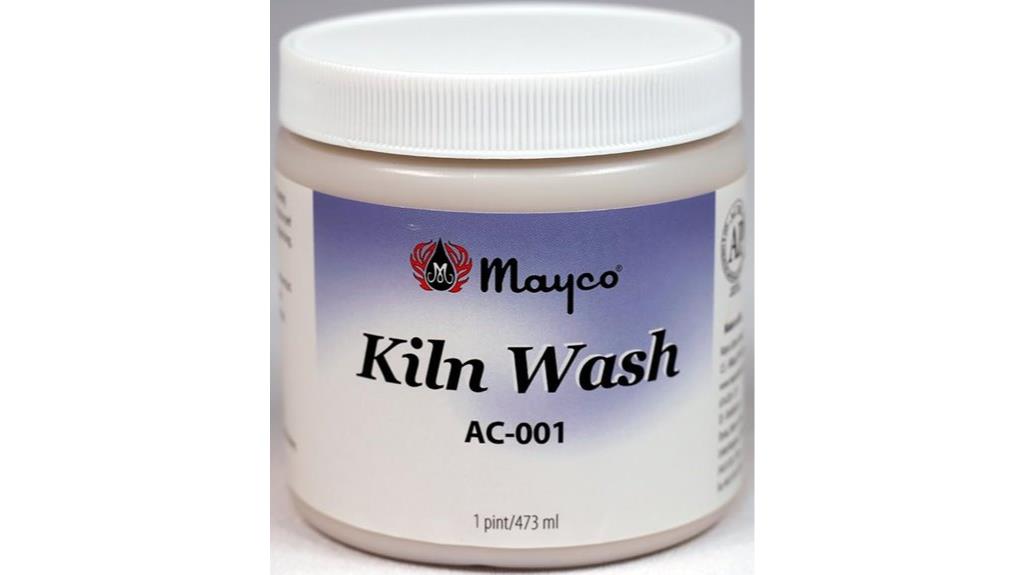

Creative Hobbies Kiln Wash AC-001, Ready to Use Liquid

Creative Hobbies Kiln Wash AC-001 stands out as an ideal choice for hobbyists and professionals who demand reliable protection for their kiln shelves. This ready-to-use liquid, packaged in a convenient pint jar made in the USA, effectively prevents glazed ceramics from sticking during firing. Applying two to three coats with a brush and allowing each to semi-dry ensures peak adhesion. It’s easy to thin with water if needed, and removing old kiln wash improves performance. This product is essential for maintaining the longevity of your kiln shelves and ensuring smooth firing processes. I highly recommend it for anyone serious about protecting their equipment and achieving consistent results.

Best For: hobbyists and professionals seeking reliable protection for kiln shelves during ceramic firing processes.

Pros:

- Easy to apply with a brush in two to three coats for optimal adhesion.

- Ready-to-use liquid that can be thinned with water if desired, saving preparation time.

- Made in the USA, ensuring quality and reliability.

Cons:

- Requires removal of old kiln wash before applying to maintain effectiveness.

- Semi-drying time between coats may extend the preparation process.

- May need reapplication after multiple firings to maintain protective layer.

Halandar Ceramic Refractory Kiln Pad with Support Stilts and Nails

If you’re looking for a reliable way to stabilize your pottery pieces during firing, the Halandar Ceramic Refractory Kiln Pad with Support Stilts and Nails is an excellent choice. This complete kit includes a durable alumina ceramic pad, 60 stainless steel support stilts, and 5 triangular pyramid kiln nails, making it versatile for various projects. It’s compatible with electric, gas, or wood kilns, and withstands temperatures up to 2462°F (1350°C). The pre-drilled grid allows flexible placement, preventing warping or shifting. Reusable and durable, this kit is perfect for hobbyists and professionals aiming for precise, stable firings of mugs, sculptures, and complex designs.

Best For: hobbyists and professional ceramic artists seeking a reliable, high-temperature support system for firing pottery, sculptures, and intricate designs.

Pros:

- Made of premium alumina ceramic that withstands temperatures up to 2462°F (1350°C) for durability and safety.

- Includes versatile support stilts and pyramid nails for flexible positioning and support of various pottery shapes.

- Reusable design with a compact storage box, making it convenient for repeated use and easy organization.

Cons:

- May require careful handling due to high-temperature materials to avoid damage or injury.

- The kit’s size and number of stilts/nails might be limited for very large or complex projects.

- Compatibility is limited to kilns that can accommodate the support grid and the size of the ceramic pad.

100 Sheets Round Microwave Kiln Papers

For anyone working on small glass fusing projects or DIY crafts, the 100 Sheets Round Microwave Kiln Papers offer a reliable solution. Made of ceramic fiber, these 4.7-inch sheets prevent glass from sticking to the kiln bottom, ensuring smooth results. They’re perfect for jewelry, beads, ornaments, and models, and come in a pack of 100 sheets, providing plenty for multiple projects. The ceramic fiber insulation reduces burning odors and protects your kiln, while acting as an effective separator. Note that these papers are designed for single use, making them a convenient, affordable choice for hobbyists and professionals alike.

Best For: hobbyists and professionals engaged in small glass fusing projects, jewelry making, and DIY crafts seeking reliable, single-use kiln papers.

Pros:

- Made of high-quality ceramic fiber for effective insulation and durability

- Prevents glass from sticking to kiln bottom, ensuring smooth results

- Reduces burning odors and protects kiln components

Cons:

- Designed for single use only, which may increase long-term costs

- Diameter of 4.7 inches may limit use to small projects

- Not suitable for large-scale or commercial production

50 Pieces Pottery Kiln Nails Ceramic Refractory Support Nails

The 50 Pieces Pottery Kiln Nails Ceramic Refractory Support Nails are ideal for practitioners who need reliable support during high-temperature firing. Made of alumina, these nails support firing up to 1380°C, ensuring durability and consistent performance. They’re reusable, lasting 5-10 firing cycles, which makes them cost-effective and environmentally friendly. Designed to resist deformation, slag, and cracking, they help maintain stability and prevent glaze issues at the kiln bottom. Their strong supporting force makes them suitable for various pottery sizes. Plus, with quality manufacturing and responsive customer support, I feel confident using these support nails to achieve professional results every time.

Best For: pottery practitioners and kiln operators seeking durable, high-temperature support nails for reliable and cost-effective firing.

Pros:

- Supports firing temperatures up to 1380°C, ensuring high-temperature stability

- Reusable for 5-10 firing cycles, saving costs and reducing waste

- Resistant to deformation, slag, and cracking, maintaining kiln stability

Cons:

- May require careful handling to prevent damage during repeated use

- Limited to ceramic support applications, not suitable for other materials

- Potential for wear over multiple firing cycles, affecting performance after extensive use

ZENFUN Kiln Support Nails and Firing Mat for Pottery and Ceramics

ZENFUN Kiln Support Nails and Firing Mat stand out as essential tools for pottery enthusiasts and professionals seeking precise, efficient firing support. This system includes a durable, reusable firing mat and 60 movable nails, allowing flexible placement for firing two pieces simultaneously. Made from high-temperature resistant materials, the mat resists cracking and slag, supporting temperatures up to 2462℉ (1350℃). Its porous design with evenly spaced holes ensures customizable support, reducing waste and improving ceramic yield. Weighing just 8.8 ounces, it’s easy to handle and enhances firing accuracy. Perfect for porcelain and other ceramics, it’s a cost-effective, reliable addition to any studio.

Best For: hobbyist and professional ceramic artists seeking a durable, precise, and cost-effective firing support system for multiple pieces.

Pros:

- Reusable for approximately 100 firing cycles, offering long-term value

- Adjustable and movable nails allow customized support and precise placement

- Supports high temperatures up to 2462℉ (1350℃), suitable for porcelain and other ceramics

Cons:

- Slightly limited in size to fire only two pieces simultaneously

- The nails and mat require careful handling to avoid damage during placement

- May need additional support accessories for more complex firing setups

Ctosree 36 Pcs Ceramic Fiber Paper Insulation Gasket or Liner

Ctosree’s 36-piece ceramic fiber paper set is an excellent choice for craftspeople seeking reliable insulation gaskets or liners that withstand high temperatures. Each piece measures about 12 x 12 inches and 1/16 inch thick, providing plenty of options for various projects. Made of durable ceramic fiber, the paper resists temperatures up to 2192°F, ensuring safe, effective insulation and preventing glass from sticking. It’s lightweight, easy to cut into custom shapes, and simple to use—just place it inside the kiln, add your glass or ceramics, and fire. Keep in mind, it’s single-use, but its performance makes it a versatile, practical tool for high-temperature crafts.

Best For: hobbyists and professional crafters engaged in high-temperature projects like jewelry making, glass fusing, and ceramic crafting who need reliable insulation and lining materials.

Pros:

- High-temperature resistance up to 2192°F (1200°C) ensures durability in demanding applications

- Lightweight and flexible, easy to cut and customize for various project needs

- Provides effective insulation and prevents glass from sticking, enhancing craft quality

Cons:

- Single-use only, not reusable after initial use

- Moderate thickness (1/16 inch) may require multiple layers for certain applications

- Cutting and handling require care to avoid fraying or damage to the delicate fiber paper

10 Pcs Kiln Paper Ceramic Fiber Sheets for High-Temperature Insulation

If you’re working on high-temperature projects like glass fusing or building insulating layers, these 10 pcs ceramic fiber sheets are an excellent choice. Made from durable ceramic fiber with a rated temperature of 2300°F (1260°C), they resist thermal shock, attack, and impact. Each sheet measures about 28 x 30 cm (11 x 12 inches) with a 0.12-inch thickness, making them versatile for repairs, insulation, or DIY builds. They’re easy to cut with a saw or knife, allowing for custom shapes. Keep in mind, these sheets aren’t suitable for food contact, but they’re perfect for high-temp applications like fireboxes and combustion chambers.

Best For: DIY enthusiasts, hobbyists, and professionals working on high-temperature insulation, glass fusing, and furnace repair projects.

Pros:

- Excellent high-temperature resistance up to 2300°F (1260°C) for demanding applications

- Easy to cut and shape with common tools like saws or knives for custom fitments

- Durable, resistant to thermal shock, attack, and impact, ensuring long-lasting performance

Cons:

- Not suitable for contact with food or edible items

- Dimensions are fixed; careful measurement is necessary before purchase to ensure proper fit

- The sheets may be brittle and require careful handling to prevent damage during installation

100 Sheets Microwave Kiln Paper for Ceramic Fiber Insulation

For artists, hobbyists, and DIY enthusiasts, Sheets Microwave Kiln Paper for Ceramic Fiber Insulation offers an essential solution to safeguard kiln surfaces and improve craft results. With 100 sheets measuring about 4.7 inches each, it provides ample coverage for multiple projects and replacements. Made from reliable ceramic fiber, it ensures excellent thermal insulation while remaining lightweight, flexible, and easy to cut or fold. This paper prevents glass from sticking, resulting in smooth, professional finishes. It’s perfect for glass fusing, jewelry making, pottery, and modeling, offering safety, cleanliness, and enhanced craftsmanship with minimal effort.

Best For: artists, hobbyists, and DIY enthusiasts seeking reliable kiln insulation and surface protection for various craft projects.

Pros:

- Made of high-quality ceramic fiber for excellent thermal insulation and durability.

- Lightweight, flexible, and easy to cut or shape, enhancing ease of use.

- Prevents glass from sticking, ensuring smooth, professional finishes on projects.

Cons:

- May require careful handling due to its lightweight and delicate nature.

- Cannot be used as a standalone kiln, only as a protective or insulating layer.

- Limited to applications involving microwave kiln use and ceramic fiber insulation.

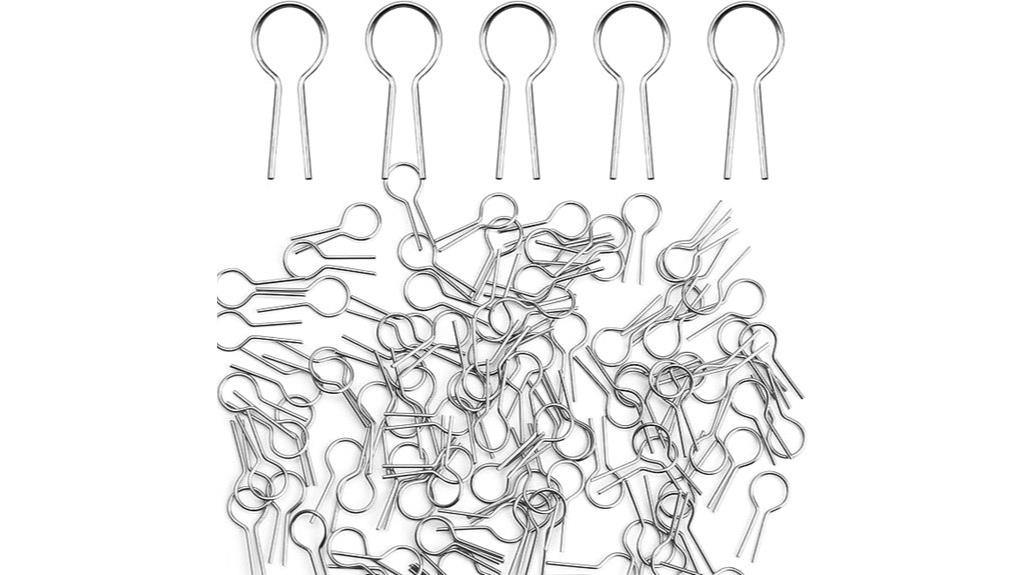

100PCS R-Shaped Hanging Burning Needles for Kiln and Glass Fusing

Are you searching for reliable tools that make glass fusing and ceramic projects easier and more precise? The PCS R-Shaped Hanging Burning Needles are perfect for embedding into ceramics, glass, or clay to create small hanging decorations, jewelry, or embellishments. These hooks can withstand up to 1350°F without discoloring or breaking, ensuring durability in high-heat firing processes. Pre-cut, pre-bent, and uniformly sized, they’re user-friendly and easy to insert into hot materials. With a bulk pack of 100 hooks, they’re ideal for both individual artists and larger projects, offering consistent results and long-lasting performance in your creative endeavors.

Best For: hobbyists, jewelry makers, and ceramic artists seeking reliable, high-heat resistant hooks for glass fusing and kiln projects.

Pros:

- Versatile for jewelry, decorations, and DIY craft projects

- Withstands high temperatures up to 1350°F without discoloration or breakage

- Pre-cut, pre-bent, and uniformly sized for easy, consistent application

Cons:

- May require bending customization for specific designs

- Limited to R-shaped hooks, which might not suit all project types

- Bulk pack may be more than needed for small or occasional projects

Liquid Kiln Wash 17.6 oz

Liquid Kiln Wash 17.6 oz stands out as an essential accessory for anyone serious about protecting their kiln shelves during firing. This protective coating prevents glazed pottery from sticking, reducing glaze runs, pot tipping, and over-firing issues. Suitable for microwave kilns, it works within temperatures of 1000-1300°C, ensuring safe, clean firings. Applying it evenly with a brush and allowing it to dry for 48 hours maximizes its effectiveness. Using kiln wash prolongs shelf life, minimizes surface damage, and promotes successful firing outcomes. It’s a must-have for professional studios, schools, and pottery enthusiasts committed to quality and efficiency in their ceramic processes.

Best For: ceramic artists, pottery studios, and pottery enthusiasts seeking to protect kiln shelves and ensure successful firing outcomes.

Pros:

- Effective at preventing glaze sticking and reducing glaze runs

- Extends the lifespan of kiln shelves by minimizing surface damage

- Easy to apply with a brush and suitable for microwave kilns within the specified temperature range

Cons:

- Not suitable for fiber-based or silicon carbide shelves

- Requires a minimum of 48 hours of drying time before firing

- Must be applied evenly and carefully to ensure optimal protection

120x130mm Microwave Kiln for Firing Ceramics and Fused Glass Up to 1200 ℃

The x130mm Microwave Kiln stands out as an ideal choice for hobbyists and small-scale artisans who need reliable, high-temperature firing capabilities in a compact form. With internal dimensions of φ75 x H90mm, it’s perfect for small ceramics and fused glass projects. It heats quickly, melting glass in just 6-8 minutes and sintering ceramics at up to 1200°C in about 15 minutes. Constructed from durable ceramic fiber, it ensures safety and longevity. Its user-friendly design makes it suitable for home use or small studios, offering efficient performance for jewelry makers and craft enthusiasts alike. Plus, at just 14.8 ounces, it’s portable and space-saving.

Best For: hobbyists, small-scale artisans, and jewelry makers seeking a compact, reliable kiln for high-temperature ceramic and glass projects.

Pros:

- Rapid heating capabilities, melting glass in 6-8 minutes and sintering ceramics in about 15 minutes

- Durable construction with ceramic fiber material ensures safety and longevity

- Compact, lightweight design makes it easy to store and transport for home or small studio use

Cons:

- Limited internal space may restrict larger projects or multiple pieces at once

- External dimensions may still require designated storage space despite its compact size

- Not suitable for commercial or large-scale production due to size constraints

Factors to Consider When Choosing a High-End Ceramic Kiln for Artists

When selecting a high-end ceramic kiln, I consider factors like temperature range and control to guarantee it meets my specific firing needs. Size and capacity are also essential, so I can work efficiently without constantly resizing projects. Finally, I look at firing speed, durability, energy use, and overall cost to find the best balance for my studio.

Temperature Range and Control

Choosing a high-end ceramic kiln requires careful attention to its temperature control capabilities, as precise regulation directly impacts the quality of your work. I look for models with digital or analog systems that accurately reach my desired firing temperatures. It’s essential that the kiln’s maximum temperature exceeds my typical needs, ideally with a safety margin—something around 2462℉ (1350℃) is versatile for many processes. Programmable temperature profiles and ramp rates are also vital, enabling me to execute complex firing schedules smoothly. I check if the kiln has adjustable thermocouples for consistent monitoring and calibration. Additionally, I prioritize reliable, high-quality heating elements that keep temperatures stable during long firing cycles, ensuring uniform results and reducing the risk of defects.

Size and Capacity

Have you considered how the size and capacity of a kiln will influence your work? The kiln’s size determines the largest pieces you can fire at once, impacting your production speed and project scope. Larger kilns need more space and consume more energy, which affects your studio layout and operating costs. Capacity, measured in cubic feet or liters, indicates how many items you can fire simultaneously, boosting efficiency for larger projects. If you’re a hobbyist or working on small-scale pieces, a smaller kiln might be ideal. Conversely, professionals or those doing mass production should consider larger models with ample internal dimensions and door openings to accommodate various forms. Balancing your space, energy use, and project needs is key to choosing the right size and capacity.

Firing Speed and Efficiency

Firing speed and efficiency are critical factors that can considerably impact your workflow and output. Faster firing speeds reduce overall production time, helping you complete projects more quickly and boost productivity. High-efficiency kilns with advanced heating elements reach temperature setpoints rapidly, saving energy and lowering costs. Precise control over firing curves and ramp rates ensures uniform heat distribution, resulting in consistent, high-quality finishes. Programmable timers and digital controls allow you to optimize firing schedules, minimizing manual adjustments and errors. Additionally, well-insulated kilns with quality refractory materials retain heat better, maintaining high temperatures with less energy input. When choosing a kiln, look for these features to enhance your efficiency, save time, and ensure reliable, consistent results in your ceramic work.

Material Durability and Quality

You are trained on data up to October 2023. When selecting a high-end ceramic kiln, material durability and quality are essential. Premium kilns are built from refractory materials like alumina, silicon carbide, or ceramic fiber, offering exceptional heat resistance and structural integrity. These materials are rated for over 1,000 firing cycles without significant wear, ensuring longevity. High-quality kiln components feature uniform density and low porosity, which help prevent cracking, slag drop, and thermal shock during rapid temperature changes. Designed to endure temperatures exceeding 2,400°F (1,300°C), these materials guarantee stability and safety during high-temperature firings. The choice of durable, high-grade refractory materials directly impacts the kiln’s performance, resistance to wear, and consistent firing results over time.

Energy Consumption and Cost

When selecting a high-end ceramic kiln, energy consumption and operating costs are critical factors to consider, as they directly impact both your budget and the kiln’s long-term efficiency. Many premium kilns feature advanced insulation technology that minimizes heat loss, helping cut energy bills. Their power usage, measured in kilowatt-hours (kWh), varies, but more efficient models consume less energy per firing cycle. Programmable controllers play a key role by optimizing firing schedules, reducing unnecessary energy use. Although high-quality kilns often require a significant initial investment, this cost is offset over time through lower electricity expenses. Regular maintenance, like inspecting heating elements and insulation, also ensures the kiln stays energy-efficient and costs remain manageable. Balancing performance with energy efficiency is essential for long-term sustainability.

Safety and Ease of Use

Choosing a high-end ceramic kiln involves more than just performance; safety and ease of use are equally important. I look for models with intuitive controls and clear digital interfaces, which help reduce mistakes and guarantee safe operation. Safety features like automatic shut-off, over-temperature protection, and emergency stop buttons are essential to prevent accidents during firing. Precise temperature regulation within ±1-2°C helps me achieve consistent results while avoiding thermal shock or damage. Ease of loading and unloading is also essential, so I prefer kilns with stable shelving and accessible door mechanisms that minimize strain and hazards. Reliable insulation and even heat distribution are critical for safe handling and uniform firing, giving me confidence during every session.

Frequently Asked Questions

What Safety Features Are Essential in Professional Ceramic Kilns?

Safety features are vital in professional ceramic kilns. I always look for automatic shut-off systems that prevent overheating, ensuring safety and protecting my work. A robust venting system is essential to handle fumes safely. I also prioritize kilns with thermal insulation to prevent accidental burns and clear, accessible control panels for easy operation. These features give me peace of mind and keep my studio safe while I focus on creating.

How Energy-Efficient Are High-End Ceramic Kilns?

High-end ceramic kilns are like well-tuned engines—they’re surprisingly energy-efficient when expertly managed. I’ve found that modern models incorporate advanced insulation and smart controls, reducing energy waste and saving costs. While they do consume significant power during firing, their precision and efficiency cut down on unnecessary runs. Overall, investing in a quality kiln means you get powerful performance with less energy drain, making your studio eco-friendlier and more cost-effective.

Can These Kilns Handle Large or Complex Pottery Projects?

Absolutely, these high-end kilns can handle large or complex projects. I’ve used them for sizable sculptures and intricate designs, and they perform reliably. Their advanced heating elements and spacious interiors give me confidence that I can fire even the most demanding pieces without worries. Plus, their precise controls ensure consistent results, making them perfect for professional artists like you and me tackling challenging, large-scale ceramic work.

What Maintenance Is Required for Long-Term Kiln Performance?

To keep my kiln performing well over time, I regularly clean the interior and inspect the elements for wear. I also calibrate the temperature controls and check the wiring for any damage. Proper ventilation is essential, and I make sure all safety features are functional. By following these steps, I extend my kiln’s lifespan and maintain consistent firing results, saving me time and money in the long run.

Are There Customization Options for Advanced Firing Programs?

Did you know that advanced kilns often offer customizable firing programs? I’ve found that many high-end models let you tailor temperature curves, hold times, and cooling rates to match your specific projects. This flexibility helps me achieve consistent results and explore new techniques. Whether you’re firing delicate glazes or experimenting with new clay bodies, these customization options make a huge difference in elevating your pottery skills.

Conclusion

Choosing the right kiln is essential for elevating your artistry, and with the options above, you’re well on your way. Remember, “a journey of a thousand miles begins with a single step,” so invest wisely and consider your specific needs. High-end kilns can transform your creative process, making craftsmanship more precise and enjoyable. Trust your instincts, do your research, and let your passion guide you to the perfect kiln for your artistic journey.